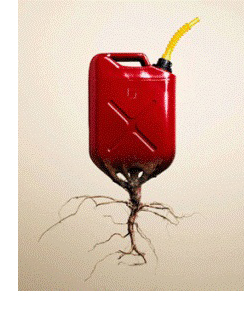

Richard Branson has backed a new process devised by a British biochemist that ferments the carbon monoxide from steel mills to produce low-carbon jet fuel.

Richard Branson has backed a new process devised by a British biochemist that ferments the carbon monoxide from steel mills to produce low-carbon jet fuel.

The smoke stacks at steel and aluminium mills and coal-powered power stations produce millions of tons of carbon monoxide, which the new process passes through a mixture of water and a bacterium in order for the carbon to be fermented into ethanol.

Once refined, the ethanol can be blended with kerosene to power commercial aircraft engines.

The impact of flying

Just one return flight from London to New York produces a greater carbon footprint than a whole year’s personal allowance needed to keep the climate safe.

Our carbon footprint is the estimated amount of carbon dioxide (CO2) given out as we travel, buy food, heat our homes and enjoy our usual lifestyles. Work out your own carbon footprint.

The average personal footprint in Britain is 9.5t. To get down to a fair share of the world’s total; this must be cut by 87%, leaving 1.2t. On every flight to New York and back, each traveller emits about 1.2t of CO2. If we fly, air travel overshadows all our other impacts.

Aviation and biofuel

The question of whether aviation biofuel is a potential environmental lifeline or simply modern-day alchemy will not be answered for years, but the aviation industry regularly heralds the biofuel of the moment as an environmental salve and this week was no different; no sooner had Thomson flown one of its aircraft from Birmingham last week with one engine running on waste cooking oil-derived biofuel than Richard Branson was announcing a new process for making aviation fuel recycled from the waste gases from steel plants and coal-fired power stations.

The question of whether aviation biofuel is a potential environmental lifeline or simply modern-day alchemy will not be answered for years, but the aviation industry regularly heralds the biofuel of the moment as an environmental salve and this week was no different; no sooner had Thomson flown one of its aircraft from Birmingham last week with one engine running on waste cooking oil-derived biofuel than Richard Branson was announcing a new process for making aviation fuel recycled from the waste gases from steel plants and coal-fired power stations.

Whilst progress continues to be made in the development of second-generation biofuels – Jeff Gazzard at the Aviation Environment Federation reports that to its credit Thomson rejected one type of fuel made from rendered animal waste, tallow, because of its impact on land use higher up the meat production chain – there remains a high risk that biofuels made from crops result in a net increase in climate-damaging greenhouse gas emissions. And whilst the recycling process backed by Branson sounds impressive, the environmental benefits of production once scaled-up remain to be seen. Virgin’s intention to trial the ‘recycled’ fuel on a route from Shanghai reflects the fact that China’s biggest steel producer, Baosteel, has already committed to the new process by agreeing to build a plant producing 30 million gallons a year within three years. Environmentalists are understandably cynical about the way that airlines use biofuel to steer the debate, but whatever the benefits of the Thomson and Virgin initiatives they may all be negated by an explosive growth in demand for aviation in China and India.

0 Comments View now